Two brilliant high school students have developed a groundbreaking, portable solution to the global microplastics crisis, inventing a pen-sized device that uses high-frequency sound waves to filter up to 94% of tiny plastic particles from flowing water.

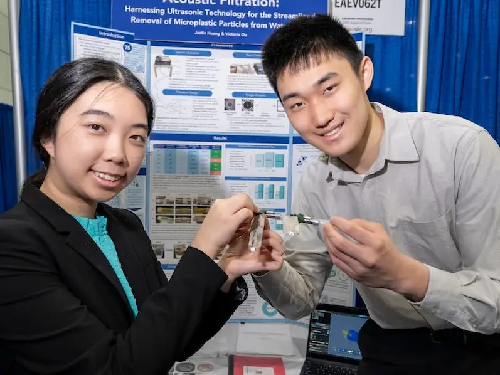

Victoria Ou and Justin Huang, both 17, from The Woodlands, Texas, were recently recognized with the prestigious $50,000 Gordon E. Moore Award for Positive Outcomes for Future Generations at the Regeneron International Science and Engineering Fair (ISEF) for their innovative project, “Harnessing Ultrasound for Microplastic Filtration.”

The device, described as roughly the size of a large pen, represents a significant breakthrough over traditional filtration methods, which are often costly, slow, or rely on potentially harmful chemicals.

Instead of a physical filter, the teens’ invention uses a small tube with two ultrasound transducer stations. These stations generate acoustic radiation forces that act as an invisible “wall of sound.”

“As water flows through the device, the ultrasound produces a force that pushes microplastics back the opposite way, but the water is still able to get through,” explained one of the inventors.

In lab tests, the prototype successfully removed between 84% and 94% of common microplastics, including polyurethane, polystyrene, and polyethylene, in a single pass. A two-stage version of the filter further increased this efficiency to over 95%.

The duo was inspired to create the device after visiting a local water treatment plant and discovering that existing facilities had no effective controls for microplastics. They envision their technology being scaled up for use in a variety of real-world applications:

- Wastewater Treatment Plants: Providing a cost-effective, chemical-free way to clean discharged water.

- Industrial Facilities: Filtering microplastic runoff, particularly from textile mills where laundry sheds a large volume of plastic fibers.

- Household Use: Being integrated into washing machines to capture fibers at the source.

The $50,000 prize money will be used to refine their prototype with professional equipment and begin the process of scaling up the technology to tackle the pervasive threat microplastics pose to human health and global ecosystems.