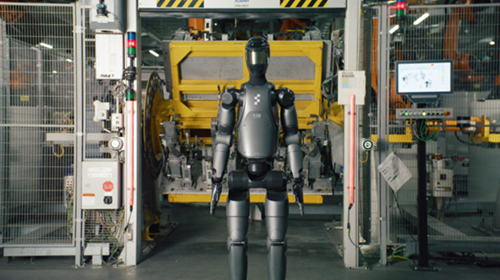

In a major breakthrough for industrial automation, humanoid robots from Figure AI completed sustained, real‑world work on a live BMW Group X3 assembly line operating 10‑hour shifts, Monday through Friday, for several months at the Spartanburg plant in South Carolina. These robots weren’t confined to labs or staged demos; they handled genuine production tasks alongside traditional manufacturing systems.

According to data released by Figure and confirmed by industry reporting, the second‑generation Figure 02 humanoid robot ran 1,250+ hours over an 11‑month deployment, contributing to the production of more than 30,000 BMW X3 vehicles and loading 90,000+ sheet‑metal parts into fixtures with an accuracy rate exceeding 99 percent. The robots also logged an estimated 1.2 million steps (around 200 miles) during their tenure.

Figure’s founder highlighted that the robots reached full‑shift productivity after about six months on the factory floor, showing that humanoid machines are moving closer to sustained operational reliability in industrial settings a major milestone beyond brief trials or controlled demonstrations.

While the pilot program has now concluded and the robots have been retired for analysis, the experience has provided critical learnings for future iterations of humanoid workers. Insights gained on performance, durability, and integration with human workers are expected to feed into the next‑generation Figure 03 platform.

This collaboration between BMW and Figure AI reflects a broader shift in manufacturing, where advanced robots are tested not just for repetitive tasks but as potential partners on the assembly line helping boost efficiency, relieve workers from physically strenuous duties, and pave the way for more intelligent automation in factories worldwide.

As companies across the robotics and automotive industries accelerate development, these real‑world deployments are a bellwether for how humanoid robots may soon become normal fixtures on factory floors not as curiosities, but as productive team members.